A legacy forged

by fire

Resilience, persistence and determination are characteristics many companies aspire to, but at LiuGong these traits have been in evidence since the very start – because there was no alternative.The company’s headquarters is in Liuzhou, in Guangxi Province. Today it’s a bustling industrial city, but when the first LiuGong factory was built in the 1950s, it was a small regional city just finding its feet.

When LiuGong was established, Liuzhou was a small city. Today, the home of LiuGong’s global headquarters is a buzzing metropolis.

We didn’t lose one person during this fire. There is nothing to fear. We can build another factory.

Li Yu, first secretary of LiuGong’s party committee.

The first group of workers, young people from Shanghai, arrived in a place many had never even heard of, to a virtually empty space.The first job for those hundreds of workers, most of them in their late teens or early 20s, was to build the factory.

The work was hard and food was scarce.

LiuGong’s first manufacturing task was to build two furnaces for the government. Li Yu, the company’s rst secretary of the party committee, once recalled that he didn’t know if the workers could do it, but he had faith not just in their skills but in their commitment.“It rained a lot. The working conditions were very basic – they often lost power and water, and they didn’t have good food to eat, but the workers all worked with great effort and nished the task 20 days before scheduled time,”he said.

And then, just two years after the site was opened, the factory and the worker accommodation burned to the ground, and the workers had to start all over again.

Li Yu told an emergency meeting, “We didn’t lose one person during this fire. There is nothing to fear. We can build another factory.”

Taking the lead

Leadership is the cornerstone of every company, and within LiuGong there is a deep respect not only for current leaders, but for those who came before: the past leaders who helped make the company what it is today.

Zhang Pei was LiuGong’s first ever Chairman and oversaw the production of the company’s first wheel loader.

Former Chairman Wang Xiaohua says each generation of leaders at LiuGong builds on the successes that have gone before.

People at every level of the company know the past leaders’ names, they recognize their achievements and they hold them in very high esteem.

People at every level of the company know the past leaders’ names, they recognize their achievements and they hold them in very high esteem.

Among the past leaders who have made their mark on LiuGong are Wang Xiaohua and Zhang Pei.

Zhang Pei spent 35 years with LiuGong, starting in 1964 and retiring as chairman in 1999. He was there when the first Chinese wheel loader rolled off the line and he was there when the company went public. Culture was always the most important thing to him.

“If you want to be successful you have to be willing to learn and adapt. China was blocked from the outside world for a long time but since the reforms we have come to really understand the value of learning from others. The reforms of the 1980s heralded a big change for us. All of our workers realized we had to do things differently, and work hard to improve our product offering. And we did. That’s the achievement I am most proud of,” he says.

“We’ve been through 60 years now and have a very solid basis for the business. We’ve made a lot of progress but we will continue to strive to do better, by investing in R&D, attracting the best talent and competing in the global market.”

For Wang Xiaohua, the tale is similar. He joined LiuGong a few years after Zhang Pei, and followed in his footsteps to the Chairman’s office.

“I was grateful for the show of trust that came with the role. Everybody has a dream and that was my dream, so I am very fortunate,” he says, though he is reluctant to take too much credit.“LiuGong’s strong position was built by the efforts of every generation. We have learned to let the past go past, follow the trends of the market and offer a total solution. There’s still a lot of space for achievement.”

As for retirement, Wang Xiaohua says the old leaders stick together.

“We look out for each other,” he says. “China’s actually a very small place.”

Corporate social responsibility

At LiuGong, there is an understanding that corporate social responsibility is just that – a genuine responsibility. From supporting villages in poorer parts of the region to stepping up in times of natural disaster, Yao Xuemei, President’s Assistant and Director of HR of LiuGong Group, says LiuGong is always ready to do its part.

In 2012, this meant a group of 20 LiuGong staff were among the first helpers to arrive in Sichuan after it was struck by a huge earthquake. The LiuGong team came together right away and by the day after the earthquake they had already organized equipment and arrived in Sichuan.

Whenever a natural disaster hits, the head office team coordinates with regional staff and dealers to get equipment and operators into the area as quickly as possible to help with rescue and relief efforts.

Closer to home, LiuGong works with communities to build capacity, in many cases literally paving the way to success. “For a lot of villages, the challenge is in getting their produce out,” Xuemei says. “To abolish poverty, you need roads.”

Across five villages in Liuzhou, LiuGong is providing resources from machines to build infrastructure to books, pens and sports goods for poor students and schools. LiuGong also installs streetlights and completes drinking water projects for the villages. Funding comes from corporate coffers and from an employee donation scheme.

“There is a national goal to realize the welfare of the whole country by 2020. In 2015, we identified five local villages to start working with and we’re looking forward to expanding that.”

Innovation through collaboration

The biggest challenge LiuGong’s Research & Development lead David Beatenbough faced when he joined the company was trying to communicate with the hundreds of engineers who now worked for him.

LiuGong’s newest generation of motor grader, the 4180D.

Dave Beatenbough, LiuGong’s R&D lead, was the first western recruit to the company.

“I don’t speak Chinese, and very few people here at the time could speak English. We all had lots to say, but we couldn’t communicate,” he says in a thoughtful American drawl.

“Then one day I put up three white boards. People often read English better than they speak it, plus engineers understand sketches and drawings.

“As we developed our new R&D center, we were thinking of the lessons learned over the years, and communications in a multicultural group such as LiuGong requires special focus. White boards everywhere is one of the best tools for communication we have found, so we created 8,000 square meters of white boards in our R&D center in Liuzhou.”

Beatenbough, one of the best-known names in the global construction equipment industry, was a significant hire for the company, exemplifying a genuine commitment to innovation and a focus on bringing in outside skills and perspectives. His recruitment took five years, not least of all because his quirky nature required a promise that he could bring his 5,000 books, including a huge collection of cook books.

“It was one of the things I negotiated,” he says. “I said ‘I’ll come, but you have to move my library’.”

More than a decade later, Dave has more than found his place in Liuzhou. He has a reputation for cooking the best steak in China from his barbecue overlooking the river and CBD – and he also has a reputation for transformation within the company.

“I was the first westerner to come into the company when I joined so it was all new territory for all of us. The processes are a lot more refined now for on boarding foreign staff.”

Dave started out with responsibility for compact equipment but by the end of his first year he had moved into R&D.

Chu Changxiang, LiuGong’s Chief Scientist.

“After three or four years we started talking seriously about planning a brand-new R&D facility, to underpin our growth. It had to house 1,200 engineers, be world class, and be a friendly and efficient work environment. We benchmarked against other companies, fine-tuned our plans then built our facility from the ground up.”

The sparkling two-toned glass facade, designed to echo the shape of the region’s famous karst mountains, includes a 350-seat auditorium and dozens of test facilities. Dave personally specified meeting room layouts, traffic flow, office arrangements and the auditorium.

It is sleek, modern and impressive, but what Dave really wants the facility to deliver is collaboration.

“In this industry people can start to work in silos. The wheel loader guy never sees anything but wheel loaders. But seeing how people do similar things leads to sharing of ideas and that in turn leads to faster development.”

As LiuGong ramps up its innovation agenda, with a range of product ‘firsts’ in development, Dave is focused, in his characteristically taciturn way, not on the machines but on the people who design them.

“My role is to create the next generation of LiuGong engineers and equip them to design the world’s best machines. Already our engineers are on par with the world’s best when it comes to theoretical knowledge. I’m working on building our engineers’ capacity to problem solve, and we’re definitely building that capability fast. The key to great engineering is not just being superb at the calculations, but understanding and solving the real problems that customers face,” he says.

Innovation in action

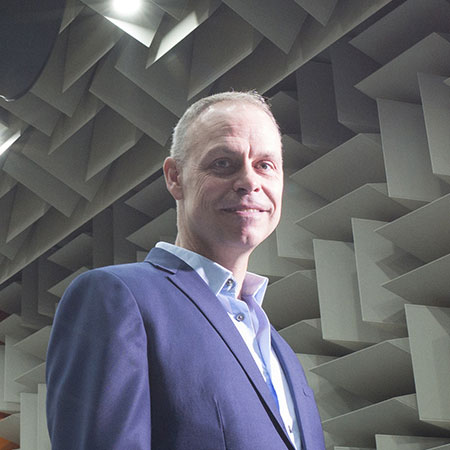

Ed Wagner stands in LiuGong’s semi-anechoic chamber, the cutting-edge noise testing facility he helped design. The room has a space age feel, with its soaring ceilings and vast metal noise attenuating walls.

Ed Wagner and his team developed the world’s first vertical lift loader, the LiuGong VL80A.

The wheel loader revolution started at LiuGong because of a combination of the right technology, the right people and the right attitude.

Edward Wagner, Director of New Technology and Testing.

A conversation in this room, used to reliably test machine noise levels, feels odd. Sounds are flat and dull and then gone.

But Ed, Director of New Technology and Director of Testing, is right at home here in LiuGong’s huge R&D headquarters. The lanky American grew up in a family of heavy highway constructors. His interest in math and science led him to a Bachelor of Science in Physics and a Master of Science in Mechanical Engineering.

Ed joined LiuGong in 2010, initially committing to just a couple of years. Now, he’s married to a Liuzhou local and building his life – and his slew of projects – in the city.

Inside the anechoic chamber is the first of Ed’s major success stories: the world’s first vertical lift wheel loader.

The VL80A loader delivers not one but two industry firsts: vertical lift loader arms on an articulating frame, and a mechanical self-leveling Z-bar bucket linkage on a vertical lift loader.

The result is a heavier tipping load and a higher lift height than conventional wheel loaders of the same power and weight. This allows customers to move more tons per hour for lower initial investment and lower owning and operating costs.

The VL80A vertical lift wheel loader is the result of a willingness to ‘think big’.

Frank Lin is in charge of research and quality assurance across LiuGong’s wheel loader and motor grader lines.

“Vertical lift has been available on skid steer loaders since the 1970s but no one had thought to do it on a wheel loader,” says Ed, who is one of few industry experts to have worked across both products.

He says the wheel loader revolution started at LiuGong because of a combination of the right technology, the right people and the right attitude.

“Without current state of the art computer technology and the very best people, this would have been all but impossible,” he says. “LiuGong supported me to hire engineer Sean Plante, the number one choice in the whole world for this kind of project. Things I couldn’t do, I knew he could, and we made it happen. The burden of proof for truly new ideas is very high, but there’s a willingness here to think big.”

Ed and his team first showcased their new wheel loader at 2017’s ConExpo in Las Vegas. “Every major competitor brought people to look at the prototype,” Ed says. “One brought 10 teams to look at it.”

There’s no time for Ed and his team to rest and enjoy their success though. They’re pushing ahead with several other new projects, and Ed says several promise to be even more exciting than the VL80A.

“We’ve got 10-plus top secret projects we’re working on and we’re aiming to bring them to market as fast as we can,” he says.

Global ideas for

global products

LiuGong’s world class research and development program is driven from its custom designed, builtfrom-scratch R&D Center in Liuzhou, but with four other centers around the world and a team of industrial designers, innovation is a truly global pursuit for the company.

It’s part of the company philosophy that the fortunes of LiuGong turn on the quality of its products. Good management is essential. A great culture is vital. The right marketing is critical.

But it all falls apart if the products aren’t right – which is why senior leaders proudly note their strong investment in recruiting the best engineers, technicians and designers.

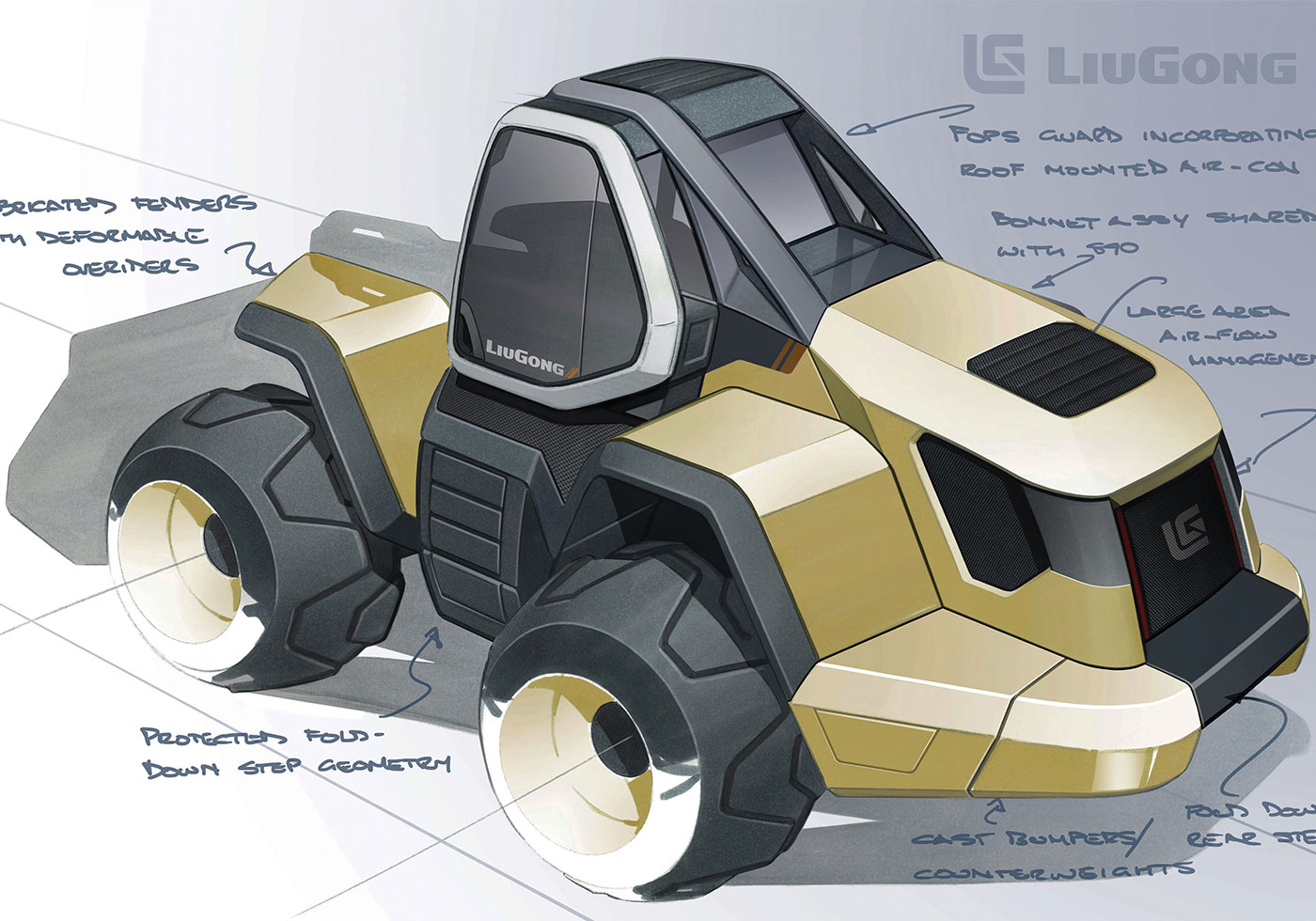

For Gary Major, LiuGong’s Industrial Design Director, the secret to innovation is in connecting with dealers and customers and being open to feedback.

“We try our best to interface with our global dealer network in order to get the customer’s opinion of the product – good and bad. This sort of information is priceless, especially as we take the brand from a domestic market into a mature global arena. It is a fiercely competitive sport we’re taking part in,” he says.

Gary is based in Staffordshire in the UK, where he heads a team of three including a senior designer with a background in the premium auto sector and a new graduate who is guiding a specialist sub-team in China.

A ‘design umbrella’ sits over all of LiuGong’s products to ensure the look is consistent.

Industrial Design is still a young department at LiuGong, but there have been plenty of achievements in the six years since Gary joined the company.

Gary himself has a long history in heavy industrial design, and he’s part of a crop of LiuGong recruits drawn from among the world’s best in their fields.

Industrial Design is still a young department at LiuGong, but there have been plenty of achievements in the six years since Gary joined the company, including the development of a ‘design umbrella’ that sits over all of the brand’s growing portfolio of products.

“With the launch of the H-series wheel loader three years ago, we had the genesis moment for our design DNA – all those little cues that will make LiuGong’s products easily recognizable even if the branding has been removed, as is so often the case with these machines,” Gary says, with considerable pride.

As well as steering the overall look and feel of the line-up, LiuGong is introducing other new approaches in the design of construction equipment, from a more willing embrace of advances in technology to better operator environments with improved ergonomics and more intuitive user-interfaces.

Meet Lai Weijun

Mining and quarrying is a major industry in China, and Lai Weijun knows that the equipment he chooses impacts his bottom line.

I first used a LiuGong wheel loader in Guangdong Province in 2002 and found the brand offered stable quality, which wasn’t common to all Chinese brands, plus the machines were highly efficient.

Mining and quarrying is a major industry in China, and Lai Weijun knows that the equipment he chooses impacts his bottom line.

Weijun is General Manager of Beitian Qingshan East Quarry in China’s Liucheng County in Liuzhou.

His operation quarries limestone, which is marketed to China’s still-robust construction industry.

“We extract limestone to sell as rock across four major specification categories. Our products are mainly supplied to Liugang, as well as to nearby cement and batching plants,” he says.

Quarrying work is demanding and the conditions are harsh. Weijun says he chooses LiuGong equipment for its ability to just keep going.

“We have 10 LiuGong machines, including three excavators, six wheel loaders and an air compressor. The excavator is a crucial part of our extraction process, exploiting ores and loading them onto trucks, while the wheel loader is used to sort and load finished rocks,” he says.

“I first used a LiuGong wheel loader in Guangdong Province in 2002 and found the brand offered stable quality, which wasn’t common to all Chinese brands, plus the machines were highly efficient. After I came to Liuzhou, I stayed with LiuGong because they’re good value, the aftersales service is very fast, it’s easy to purchase accessories, and the quality remains reliable. The excavator’s fuel consumption is equal to that of an imported machine, and the air compressor’s fuel consumption is even lower than an imported machine.”

Going public

As Feng Li reminisces About TianJin’s evolution from state-controlled entity to publicly-listed company, his four and half year old granddaughter Si Xuan plays at his feet, unaware of the role her grandfather played in this critical part of LiuGong’s history.

The Chairman chose to go public, to focus on market expansion and product development.

Former LiuGong Group President Feng Li is enjoying spending time in retirement with his granddaughter Si Xuan.

Li was Director of the Enterprise Management Department when LiuGong launched on the Shenzhen Stock Exchange in 1993, and like everyone else in the company, he was in uncharted territory.

“We knew nothing about going public. Nobody had any experience in it. We couldn’t learn from others, because we were the first. We were the first company in Guangxi Province to test ourselves in the public domain, and we were the first overall in the construction machinery industry. But our Chairman Zhang Pei said we should try, so we did,” he says.

The Chairman chose to go public, to focus on market expansion and product development. Some of the other companies that followed LiuGong onto the stock exchange were unsuccessful, but LiuGong was quick to adopt new practices that helped it succeed.”

Not that it was easy.

“There were many setbacks,” Li says.

As a state-owned company, LiuGong had a lot of work to do to switch its mindset from a planned production approach to a market economy. The period after 1993 represented a big boom, bringing in a lot of cash flow and allowed the company to embed its new management and workforce concept. LiuGong was the first company to build a dealership model with its own service and sales representatives, for example.

Li says that recalling the period after the public listing brings him great satisfaction. “LiuGong’s third and fourth decades were unforgettable, and things have only got better since then,” he says.

Li believes bold, visionary leadership sits behind LiuGong’s string of industry ‘firsts’. “From the time we went public and onwards, there was a big focus not just on product development and cash flow, but also on brand management and expanded product offering through strategic M&A decisions. That led us to achieve record sales revenue in the year I retired,” he says.

As for that retirement, Li spends part of his time on the Board of Directors of an auto company, but his main goals are family, travel, and his beloved garden.

“I want a happy, healthy, long life,” he says, as little Si Xuan climbs into his lap.

World travelers

Part of LiuGong’s global strategy is about recruiting locals who know their local market. But part of being a global company is also about sending people to other regions, and bringing people from other regions into China.

LiuGong’s global expansion has provided the opportunity for service staff to travel the world.

LiuGong’s people have taken on some of the world’s most challenging environments, from the frozen Russian Tundra to sandy deserts and even the South Pole. For some, coping with extreme conditions has been the biggest challenge. For others, getting used to new languages, customs and food have been the toughest part. For all, it’s been the opportunity of a lifetime.

Many find that in their early trips overseas, the first thing they do is go looking for Chinese food but the lure of a new cuisine eventually wins out, with people naming dishes from mushroom soup to Caesar Salad among their new-found favorites.

Deng Tao currently runs LiuGong’s Russia operations, but he’s covered a lot of ground – Pakistan, Thailand, Poland, Turkey, Serbia, Hungary, Germany and Scandinavia.

As an experienced world traveler, he’s learned a thing or two.

Like others who have taken on the challenge of an overseas post he knows that you can’t think in a ‘Chinese’ way, you have to think in the local way. Sometimes there can be conflict but diversity is good – helping people to be more open minded and work through difficulties.

LiuGong equipment was chosen for the Zhongshan Scientific Station at the South Pole.

It was a challenging and sometimes dangerous 18 months but also completely unforgettable.

For Yan Wei, LiuGong offered the kind of opportunity most people can only ever dream of – his job took him to the South Pole, where for 18 months he worked on the maintenance, management and operation of LiuGong machines at the Zhongshan Scientific Station and also supported work at other stations.

“The trip from Shanghai took 28 days by ship,” he recalls. “It was an incredible experience. There are of course no plants on the pole. Everything the stations need is delivered by ships – once per year. One of our food delivery vehicles fell through the thin ice so that food was lost. It was a challenging and sometimes dangerous 18 months but also completely unforgettable,” Wei says.

The trip was also a good opportunity to show the ability of LiuGong’s machines to work in very difficult conditions. LiuGong was highly praised by the scientific community.

Deng Tao’s experience doesn’t have quite the same ring of adventure, but it has been effective in reminding him what he loves most about home.

“I miss my wife, I miss my children, and I miss my mum’s cooking!” he says.

Following our own course

LiuGong acquired the Dressta brand in 2012 as part of its strategy to expand its European footprint.

Ten years back, many European manufacturers were rushing to set up factories in China. But LiuGong was heading in the opposite direction, cementing its manufacturing and sales capability in Europe.

In 2012, LiuGong acquired Dressta, a brand with a long-established reputation, a product line that was complementary to the LiuGong range, and a manufacturing, sales and service structure that was already up and running. It was a natural fit, and five years later the benefits of the acquisition are becoming clearer every day.

For Howard Dale, Dressta Chairman, the deal was a cross cultural investment in talent and capability.

“This made sense in so many ways. To be successful in Europe, manufacturers need people on the ground and they need to be close to the dealers and customers they serve.”

Howard, originally from the UK, has extensive experience with global brands and speaks with confidence and enthusiasm about the market.

“Europe is a nuanced market. Customers have specific expectations around fit and finish and different regulatory environments. For instance, Italy and France both require a narrower undercarriage to meet transport and trucking regulations,” he says.

“Acquiring Dressta gave LiuGong access to Europe in a very structured way, and its Polish facilities have now become the European manufacturing hub for LiuGong.”

With its renowned crawler dozer range, Dressta filled a market gap for LiuGong. “LiuGong really needed a crawler dozer, and Dressta was one of very few manufacturers to own their driveline technology,” Howard says.

The challenge in any merger or acquisition is always brand management, and Howard says LiuGong has taken a practical approach to this.

“The company has done very well in allowing the two brands to be separate, only taking advantage of natural synergies, never trying to force synergies where they don’t really exist.”

While the benefits for LiuGong have been an entry in Europe and an expanded product range, the upsides for the Dressta brand include global expansion and its first all new product in decades.

“Dressta was always a regional brand, not a global brand, but since it was acquired there have been opportunities with LiuGong dealers in new markets.”

“The biggest gains have come in the past 18 months, where we’ve really started to see the fruits of the investment. We’ve recently launched the Dressta S Series compact range, our first all new designs in 20 years.”

Dressta and LiuGong continue to become more integrated, with manufacture of the compact crawler models now based in China, while the Polish factory continues to produce the bigger machines.

“We’ll see over the next few years that the operation in Poland will be recognized as a worldclass manufacturing facility,” Howard says.

LiuGong in Morocco

Casablanca, the city immortalized by the 1942 Humphrey Bogart movie, is the bustling port and commercial hub of western Morocco. It features a coastline on the Atlantic ocean, an eclectic blend of architectural styles and one of the African continent’s leading LiuGong dealerships: Mecomar.

Mecomar is a long-established and well-respected business in Casablanca. It has been a LiuGong dealer since 1998.

“We chose LiuGong loaders at the beginning for their quality, and we have continued to evolve with LiuGong as the product line developed,” says Mecomar’s Rachid Berrada.

Morocco’s challenging terrain, from mountainous areas to the Sahara desert, calls for tough equipment, and with a strong mining and construction sector, Mecomar has seen a lot of demand for reliable LiuGong machines.

“For public projects, machines are used in the ports, on roads, for work in villages or on black spots in the city. Among our private customers we supply to large and small fleets, primarily for projects like quarries and rock sites,” Rachid says.

Recently, LiuGong and Mecomar worked together to open a vocational training school in Morocco, using LiuGong loaders, excavators and dozers. Rachid says this project reflects the relationship between Mecomar and LiuGong, which is about good outcomes for everyone involved.

“Our relationship must be based on a win-win partnership. Our interests and concerns must converge towards the same goal, which is the development of the LiuGong brand while ensuring an international image worthy of what it represents in the business sector,” he says.

“What is important for the customer is that we listen, have the best commercial and technical advice, offer excellent after sales service which is fast and efficient, and of course the availability of spare parts. Overall, we must provide a commercial offering which is convincing compared to the competition.”

Challenges, lessons and success in India

We are very proud of the fact that we are number two for motor grader sales and for having 25% market share in India from last three years.

There is a lot of talk in manufacturing circles about whether India might be ‘the next China’. For LiuGong, it is. LiuGong has made a significant investment in India and it’s already paying off.

Within a short span of time, LiuGong has become a trusted and preferred brand for customers in India.

According to Nischal Mehrotra, director of sales and service, who has been with LiuGong for 10 years, “We are very proud of the fact that we are number two for motor grader sales and for having 25% market share in India from last three years.”

LiuGong is one of the most trusted brands for wheel loaders in India, retaining the number one position for 5-ton wheel loaders with 43% market share for the last 8 years and ranking third for overall wheel loader sales in India.

LiuGong India has a state of the art manufacturing facility, its own local research and development center and a training center for its 250 employees.

There are more than 4,000 LiuGong machines at various prestigious Indian companies, working in road construction, mining and quarrying, ports, steel plants, hydro power plants, thermal power plants, cement plants, industrial applications and material handling.

“It is exciting to see that LiuGong is playing such a significate role in the continuous development in India,” Nischal says.

While the results have been impressive, they have not come easily. The challenges have been plentiful. Initially mistakes were made but the team worked really hard to get the product offering right and adjusted its management style to suit the market. There is now more emphasis on after sales support, including flexible warranty terms and direct monitoring of key account and retail customers. This has engendered greater trust from customers, which in turn is leading to repeat purchases and referrals.

Today, LiuGong India is much closer to customers, with all states of India served through 16 dealers and more than 50 touch points. Nischal expects LiuGong India to continue to grow and service markets beyond its borders.

LiuGong India is already exporting products to neighboring countries. In the future they hope to expand the product lines and develop India as a manufacturing hub for LiuGong by taking advantage of access to materials and highly skilled labor in the country.

the market. There is now more emphasis on after sales support, including flexible warranty terms and direct monitoring of key account and retail customers. This has engendered greater trust from customers, which in turn is leading to repeat purchases and referrals.

Today, LiuGong India is much closer to customers, with all states of India served through 16 dealers and more than 50 touch points. Nischal expects LiuGong India to continue to grow and service markets beyond its borders.

LiuGong India is already exporting products to neighboring countries. In the future they hope to expand the product lines and develop India as a manufacturing hub for LiuGong by taking advantage of access to materials and highly skilled labor in the country.

Product pride

For everything that LiuGong stands for, ultimately the company lives and dies by the quality of the products it sells. With 32 product lines across the Group, that’s a lot of quality control.

It’s also a lot of hard work, commitment and focus, as leaders past and present understand.

Zhang Er’ping expects a Chinese brand to lead the world, and soon.

Where it all started: the wheel loader

1966 LiuGong produces China’s first wheel loader

1986 the second generation ZL loaders are developed

1998 the third generation ZL50G is manufactured

2013 the brand-new generation CLG series is launched

2016 LiuGong launches the world’s first vertical lift loader

Zhang Er’ping, former LiuGong Chief Engineer and later Vice President of the LiuGong Group, has a near permanent smile. He’s patient, generous, and incredibly proud of his career with the company, and especially its position as one of the giants of wheel loader manufacture.

He remembers his first day on the job in 1982 and the excitement of working with a famous company which provided him with a monthly salary and a 12 Yuan allowance.

He also remembers the key milestones of wheel loader development that led the company to a point where, today, a wheel loader is produced in under eight minutes.

“So much new technology was introduced during my time,” he says.

The second generation delivered new technology such as single title arm and steering hydraulic control, while the third added electronic controls – both were best sellers. When LiuGong added side dumping it achieved 60-70 percent market share.

The first wheel loader model to go overseas went into South Korea in the 1980s. The company learned a lot from overseas markets, and was able to use a lot of these learnings in the domestic market too, from emissions standards to improving comfort.

Zhang Er’ping believes the world will be ready for a Chinese brand to be number one, someday soon.

“I hope I get to see it,” he says, signature smile firmly in place.

Excavators have become a key part of LiuGong’s product range.

Huang Min says he is most proud of the way LiuGong has been able to quickly get its excavator business into such a positive position.

Huang Min, Vice President, TianJin Machinery (center).

Excavator expansion

1992 LiuGong starts its excavator business with the WY40

2005 LiuGong Excavator Division is established

2012 LiuGong Excavator wins the National Quality Award

2015 Successful trial production by the China / India team and first excavator produced in Brazil

2016 Excavator with 4F engine launched LiuGong into the high end global market Huang Min thinks an excavator line is essential to any construction equipment company that wants a place on the world stage, which is probably no surprise, given that he’s in charge of the company’s excavator business. Still, he makes a compelling argument.

“Our former Chairman spent a lot of time abroad, analyzing international companies, and found that not only did many of them have excavator businesses, but that the excavator was a dominant part of their business. So, we decided to take on excavator expansion as one of our strategies,” he says.

It was far from smooth sailing, though. At first, the company used domestic technology to manufacture the excavator. It was an unsuccessful venture.

Huang Xiangquan, who was general manager of the excavator division from 2002, recalls plenty of early challenges, but lots of proud moments, too.

“During my time we made three generations of excavators and saw a huge amount of progress. We were in the leading position in China during this time. From my point of view, an enterprise’s strategy should take the product strategy as the core. Only when you get the product strategy right can you realize a better corporate strategy.”

Xiangquan says the first challenge for LiuGong was proving itself to customers.

“With the introduction of our C series products, we began to develop sales and marketing channels and by the time we launched the D series we had a proper R&D system.” Huang Min says he is most proud of the way LiuGong has been able to quickly get its excavator business into such a positive position.

“People were not initially convinced about our excavators but now our own people and our customers believe that we are on a sustainable path.”

LiuGong will have capacity to produce 20,000 forklifts a year by 2020.

We have a strong focus on technology and quality, and we invest a lot in product and market development. I’m excited about the future for LiuGong Forklift.

Wang Taiping has big ambitions for LiuGong’s forklift business.

Moving into forklifts

2002 LiuGong’s first forklift division founded in Shanghai

2008 New forklift factory starts production in Liuzhou

2011 LiuGong Forklift becomes the first Chinese OEM to join the Industrial Truck Association

2012 Named in ‘top 10 emerging brands’

2013 Sales volume exceeds 10,000 units

Wang Taiping, LiuGong’s Vice President Forklifts, has big ambitions for his product line.

“We’re aiming for a total production capacity of 20,000 units by 2020,” he says, and he’s confident it will happen.

The forklift position is getting better and better, with excellent quality and performance compared to a lot of competitors. Already there are more overseas than domestic customers, but there is plenty of room for further globalization.

Two years ago, a factory was established in Argentina in cooperation with a local dealer and LiuGong has already achieved 15 percent market share.

Taiping came to his forklift role with a lot of overseas market experience, and he is applying what he’s learned to build the forklift operation strategically and soundly.

“We have a strong focus on technology and quality, and we invest a lot in product and market development. I’m excited about the future for LiuGong Forklift.”

The legend of 899

In 2002 LiuGong tripled its monthly wheel loader production.

Ask anyone at LiuGong about the legendary story of 899, and watch the smile spread across their face. From the Chairman of the Group to past leaders, from factory workers to admin staff, everyone knows the story, and everyone has the same reaction when you ask about it.

The story of 899 is virtually a fable, summing up the heart and soul of the company, except it’s true.

As current Chairman Zeng Guang’an recalls, smiling, the legend was born in 2002.

“China was expanding very rapidly, with lots of infrastructure projects. Demand was booming and no one could keep up,” he says.

“To that point, we had been producing at most 300 wheel loaders per month but in April 2002, we produced 899 wheel loaders in a single month.

“No one thought it was possible, but we did it and it led to a huge change of mindset. Now people believe nothing is impossible.”

LiuGong Group President Zheng Jin is similarly delighted at the mention of 899.

“The dealers were at our door waiting for product. Our workers, our leaders, our families, we all worked hard and contributed to make this happen,” he says.

The whole team pulled together to work around the clock.

“The chairman at the time would eat his dinner in the factory so he could keep working and get the product out. It was difficult, but our people have incredibly strong spirit.

“This is one of my proudest memories of my time with LiuGong. There are so many stories from that time, so many people who did so much. We found efficiencies and we turned impossibility into possibility.”

The never-give-in mindset has seen LiuGong continue to push the boundaries and achieve new goals. Today, the factory that used to turn out 300 machines in a month can produce over 4,000 per month.

“Most companies build a huge factory with low efficiency that leads to low utilization,” Chairman Zeng says. “We focus on improving the efficiency of our existing facilities. Our technology improves and our people are always improving too.”

In good company

You can learn a lot about a person from the company they keep, and the same is true in business. As LiuGong has grown and developed, the leadership of the company have made some strategic decisions about partnerships, joint ventures and supplier relationships. Among the key relationships are those with engine manufacturer Cummins and transmission and axle manufacturer ZF – two world-class brands.

Steve Chapman from Cummins tours LiuGong’s facilities with former LiuGong President Yu Chuanfen.

Steve Chapman from Cummins says shared values are at the heart of all of Cummins’ partnerships.

“We’ve learned many lessons about basing our business on values. Just over 15 years ago, we looked at ourselves, and we realized that while we stated a commitment to a cleaner, healthier and safer environment, we weren’t truly living to meet that commitment in all of our actions. So, we changed ourselves, focused on living our values, and became a fantastic commercial success as well.

“We treat partner selection very seriously. Part of the partnership decision is driven by the business. We’re looking for partners that offer strengths or business profiles that are complementary to ours. But a key part is also shared values. LiuGong and Cummins share values such as integrity, excellence and teamwork.”

While the partnership is working well, Steve says it has not been without its challenges.

“After developing engines for both loaders and excavators, and then building a world-class plant, the market volumes fell significantly for three to four years,” he says, but the focus remained on the future.

“The biggest success has been the establishment of an outstanding engine plant, staffed by a committed and capable group of people. I see the companies continuing to bond together to grow volume, achieve strong market positions for loaders and excavators, and build global business outside China.”

The construction machinery market in China has huge potential. China has become the world’s largest manufacturing base of construction machinery, and its construction machinery industry has the highest level of internationalization. Together with public investment in China’s infrastructure this offers great opportunities for both LiuGong and ZF,

ZF board member, Wilhelm Rehm.

It’s a similar story from Wilhelm Rehm at ZF.

“Since 1995, ZF and LiuGong have been operating a joint venture company in Liuzhou for the production of transmissions and axles for construction machinery. As far as ZF is concerned, we are glad and proud to be a small part of the unique success story of LiuGong, a company that meets the highest quality specifications worldwide, and perfectly matches our corporate philosophy,” he says.

“The cooperation between LiuGong and ZF is more than a business partnership. Our good personal relationships, based on fairness and friendship, which have developed during the years of our cooperation are the cornerstone of our prosperous joint venture.”

Wilhelm says a common understanding and vision is crucial to successful partnerships.

“Quality, technology leadership and innovation have shaped ZF’s identity from the outset. Together with our partner OEMs like LiuGong we will ensure that these ambitions are realized, enhancing our global footprint. Goals can only be achieved when both partners are pulling in the same direction.”

That includes being prepared to weather the tough times.

“In 2003, our joint venture reported a negative result. In addition, the ups and downs of the construction machinery business, especially the strong decline in 2008, were a big challenge.

“We met these challenges by setting up a stable management team. Further cornerstones have been the opening of our production for third-party customers as well as the implementation and extension of our production system. The continual development of our product portfolio and engineering competencies in Liuzhou have been a main factor of our shared success.”

Wilhelm sees a strong future for ZF and LiuGong.

“The construction machinery market in China has huge potential. China has become the world’s largest manufacturing base of construction machinery, and its construction machinery industry has the highest level of internationalization. Together with public investment in China’s infrastructure this offers great opportunities for both LiuGong and ZF,” he says.